Pads

The pad is the part of the machine that physically transfers the ink from the cliché to the piece to be printed.

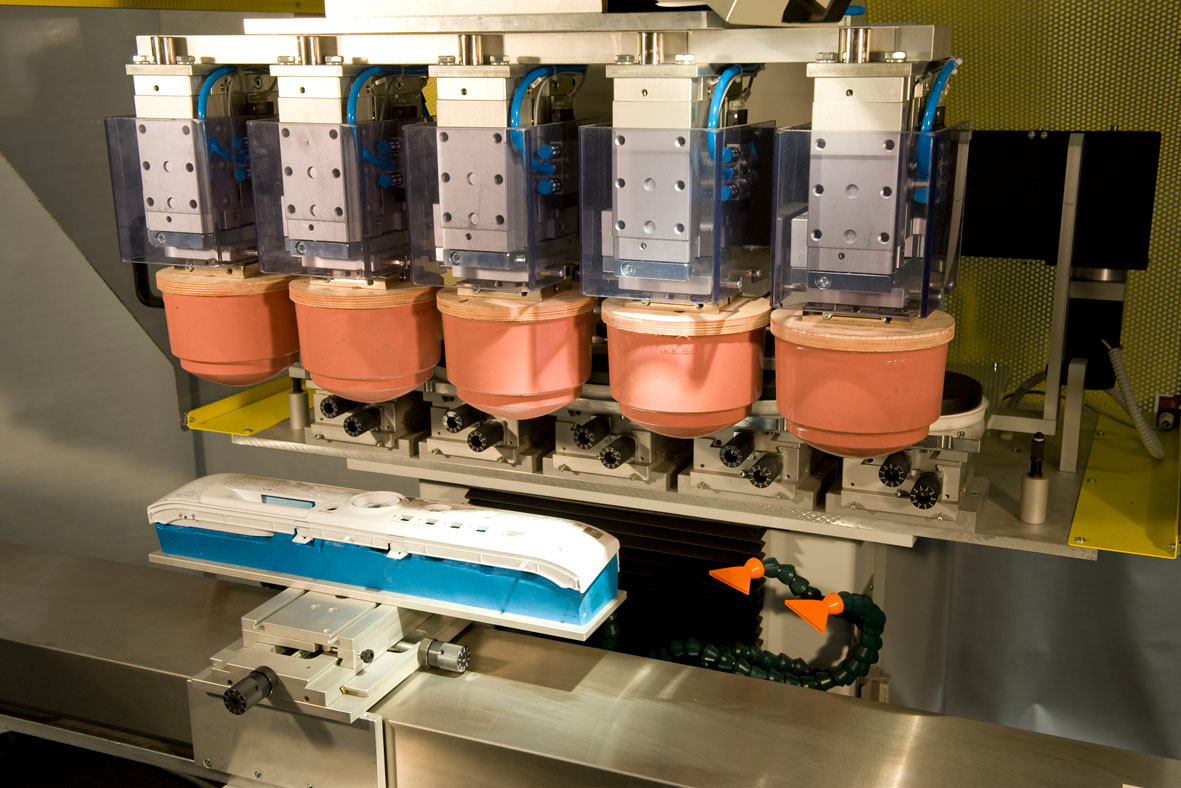

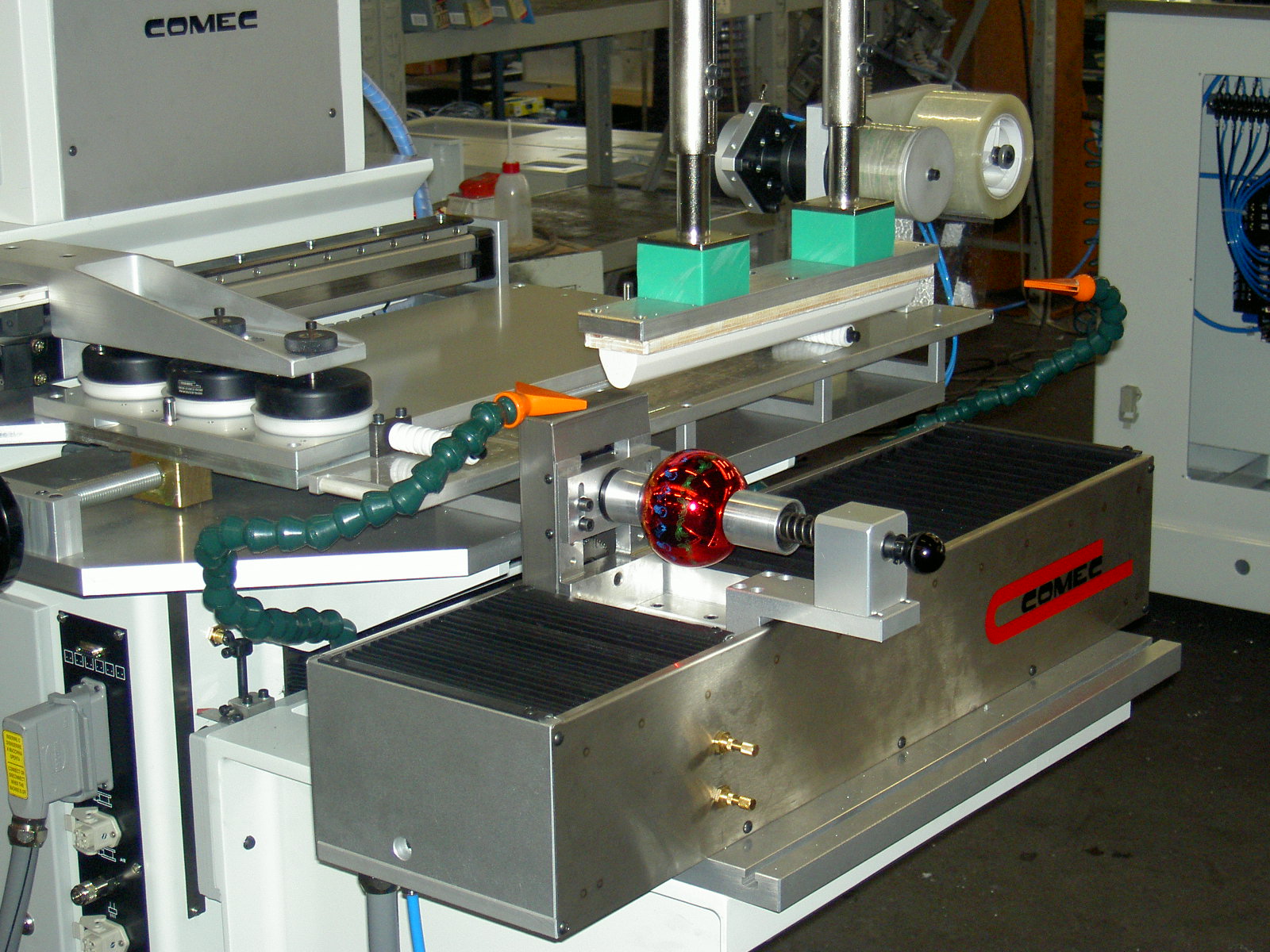

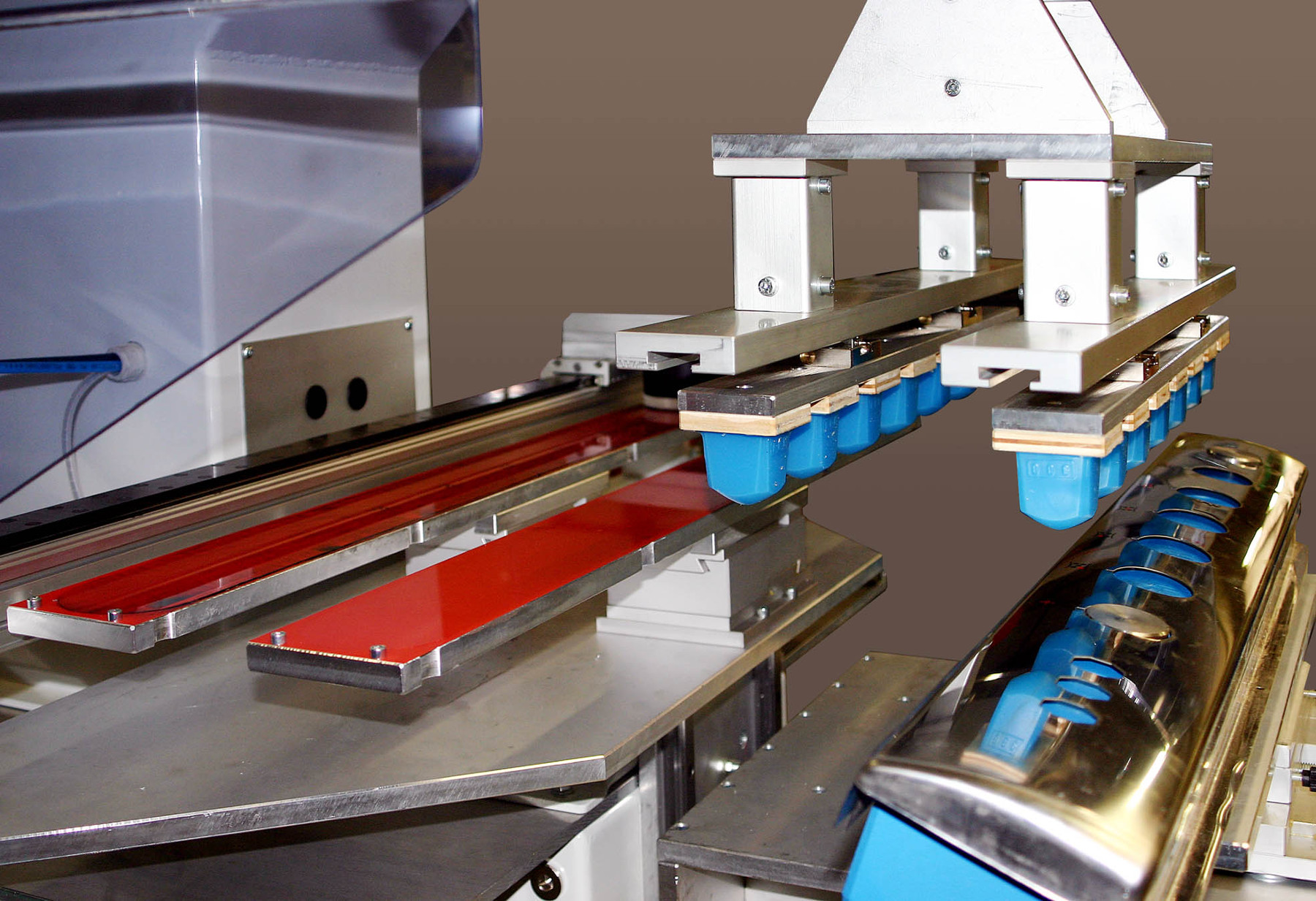

Made with special silicone rubbers, it can have different shapes and sizes depending on the object to be printed. It is placed on a base of wood or aluminum arranged for insertion in different machines.

Just the material which it is composed of confers to the pad specific properties.

First, it is a long-term support because it is lacerating resistant from the mechanical standpoint and from the chemical it is resistant to substances contained in solvents and inks. It is therefore several times reusable, because its shape and its hardness, even when subjected to pressure, remain stable thanks to its elasticity.

Especially the silicone resin guarantees excellent performance in the delicate ink pickup and release step, so as to obtain a perfect transposition of the image.

The pads, just because they are able to fully release the ink, are also easy to clean, thus reducing the maintenance.

Choice Of Pad

Every object that we have to print requires a specific size and shape pad. The Comec Italia catalog includes more than 1500; furthermore our technicians are always working to study the most suitable forms for all your printing needs, providing custom-made pads.

But how do you choose a pad?

The parameters to be determined are mainly three: size, shape, hardness.

As it regards the size the basic indication is that the size of the pad must be at least 20% larger than the print area, to allow a correct positioning of the graphic, whereas the material of which it is composed, once compressed during printing, expands itself.

The hardness and the shape instead are defined by various factors. First of all we must consider the surface to be printed: if it is flat or curved, and which shape and dimensions has; in this phase also the size and the position of the print area are important.

Secondly, it is necessary to evaluate the physical characteristics of the surface to be printed, if it is smooth or rough, what kind of material it is, its potential degree of ink absorbency.

Summing up and studying all this data you can understand what is the most suitable pad to each print work. The hardness is expressed in Shore A, units of measurement that refers to the hardness of the elastic products. As an example, for rough surfaces is recommended to use soft pads, hardness 02/04 Shore A.

Every hardness degree corresponds to a different color of the pad: Shore A 4 White, Shore A 6 Green, Shore 8 Yellow, Shore A 12 Blue, Shore A 16 Red.

Not only, but antistatic pads (RED 1) are also available, to reduce the risk of contamination of the printing area.